NOTE-- THIS IS A WORK IN PROGRESS -- PLEASE CHECK BACK for FINAL REPORT.

Presently, a more complete commentary exists on Facebook:

https://www.facebook.com/billhuston/media_set?set=a.10208436115357131.1073741862.1133803981

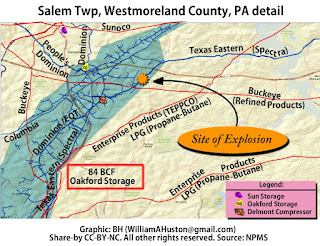

I've been digging into the 4-29-2016

Spectra/Texas Eastern Transmission (a/k/a TET, TETC, TETLLP, TE, or

TETCO). failure this past week. This was one of the top 5 worst pipeline

accidents US History in terms of impact radius. Here is a photo album

with my results so far. Scan though all the photos in this album.

SUMMARY OF MY FINDINGS:

Here are the factors I think contributed to the failure and the severity of the impacts:

1) I believe the root cause will be found to be due to corrosion caused

by stray DC currents caused by imbalances or errors or interference in

Cathodic Protection systems of the 4 different pipes in the ROW. This is

extremely tricky to get right, and is almost certainly the cause of the

severe corrosion and near-failure of the Keystone-1 pipeline west of

St. Louis (Julie Dermansky reported on this for DeSmogBlog).

2) It took 1 hour for the TETCO workers to close all the right valves. This contributed to a long burn.

3) There were 4 segments all interconnected. This means even after they

found and closed the right valves, all of that gas upstream and

downstream to the nearest block valves had to drain out and burn. I

haven't seen official reports about duration, but I'm guessing the fire

burned for at least 4 hours, till noon or so. This really made the

impacts much worse than if they could have isolated the fault in a

*single* segment.

4) Part of the problem is the loss of records

about the pipeline. TETCO went to FERC in 2013 to abandon some or all

of 750(!!) facilities which they had lost track of, as they lost all of

their records after a flood in 2001 (Tropical Storm Allison).

5) The official PHMSA report reveals that one of the four parallel and

interconnected lines in the same ROW was taken out of service a week

before the accident, was blown down and under maintenance. What are the

odds that a maintenance worker accidentally closed an incorrect valve on

a pipeline which is already charged to 98.9% of MAOP, because he lacked

proper records? What happens to the pressure in that segment? Hmmm....

6) The pipeline may have been carrying > 12% ethane, which is more explosive, due to a special waiver issued by PHMSA.

7) The MAOP of the pipeline should have been lowered in 2006 due to a

change in Class caused by an increase in the number of human-occupied

structures within 220 yards (660'ft) of the centerline. PHMSA languished

on the request (allowing them to operate at unsafe pressures) until

2009, when they granted a waiver!!

8) When the pipeline

ruptured, it was operating at 98.9% of MAOP. This is what happened when

San Bruno popped. The problem operating so close to MAOP is that there

can be pressure fluctuations caused by physics of gas transmission (or

human accidents). Suddenly, there can be a surge (like of someone closes

a block valve on a pressurized segment.)

9) There appears to be some involvement of a storage well, part of the Oakford system.

I'm sure there is more but this is what I've found so far.

All images in this series are (C) 2016 WilliamAHuston@gmail.com Share-By CC-BY-NC - All other rights reserved

1 comment:

Brilliant work Bill!

Post a Comment